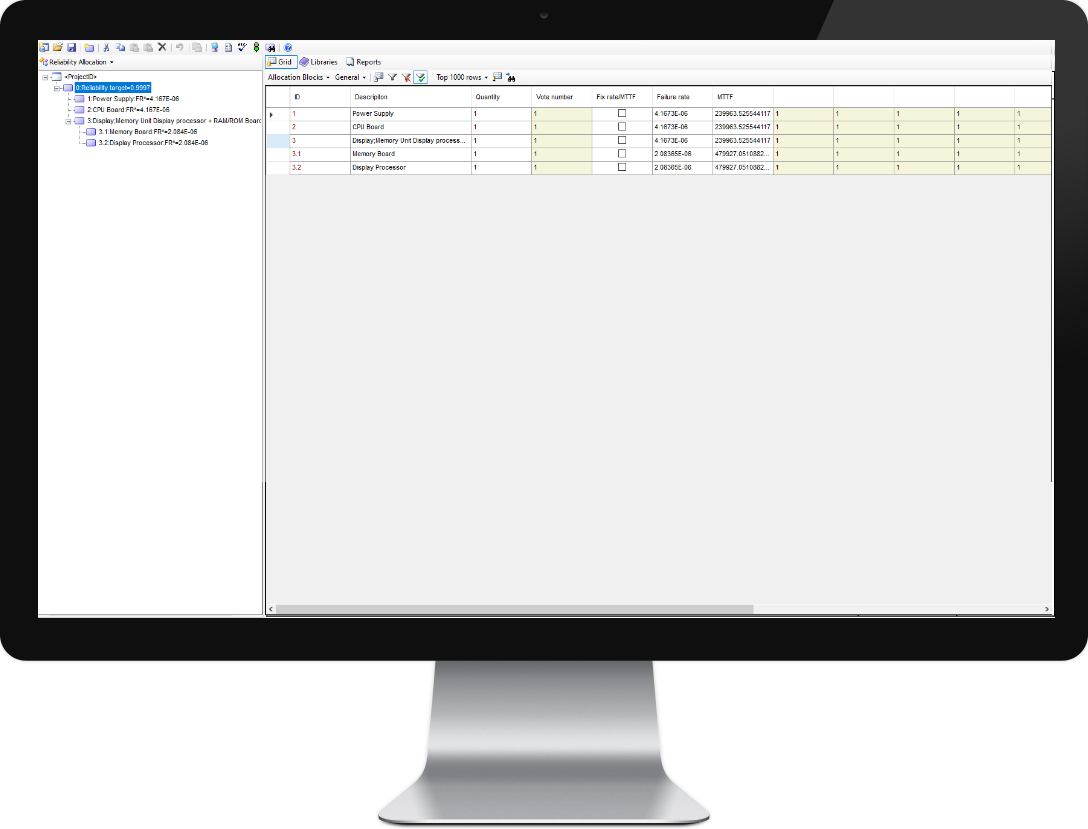

Reliability Allocation

in Reliability Workbench

Download Reliability Workbench and access our reliability allocation module and analyze the reliability trends in your system. Reliability allocation apportions a system target reliability amongst sub-systems and components. It is a useful tool at design stage for determining the required reliability of equipment to achieve a given system reliability target

- Quickly build the allocation hierarchy using drag and drop

- Access your reliability data using our extensive import facilities

- Non-restricted equal allocation

- Non-restricted graded allocation

- Non-restricted proportional allocation

- Non-restricted redundancy proportional allocation

- Non-restricted reliability re-allocation

- Restricted direct research allocation

- Extended graded allocation

Our software has been in continuous development since the 1980s and is the recognized standard for safety and reliability professionals.

Using Reliability Allocation to Apportion Reliability

Reliability allocation sets reliability goals for individual subsystems in order to meet a system reliability target. Reliability values may be allocated using a variety of methods based on complexity, criticality, achievable reliability, or other factors that are deemed appropriate.

Read More...

Read More...

Contact Sales | Download Free Trial

Why choose Isograph?

Our Credentials

Partners.

Premium Support

Industry Standards

Development

Download Free Trial