As many of you requested I have posted the recording titled "Reporting on a Fault Tree Model" . In this webinar we showed a few of the many features available in the report designer.

https://attendee.gotowebinar.com/recording/6873753437059734017

One of the most important aspects of your reliability or safety studies is the creation of professional standard reports that will enable you to present the results in a clear and understandable form to colleagues, management, customers and regulatory bodies.

HOW CAN I USE THE REPORT DESIGNER?

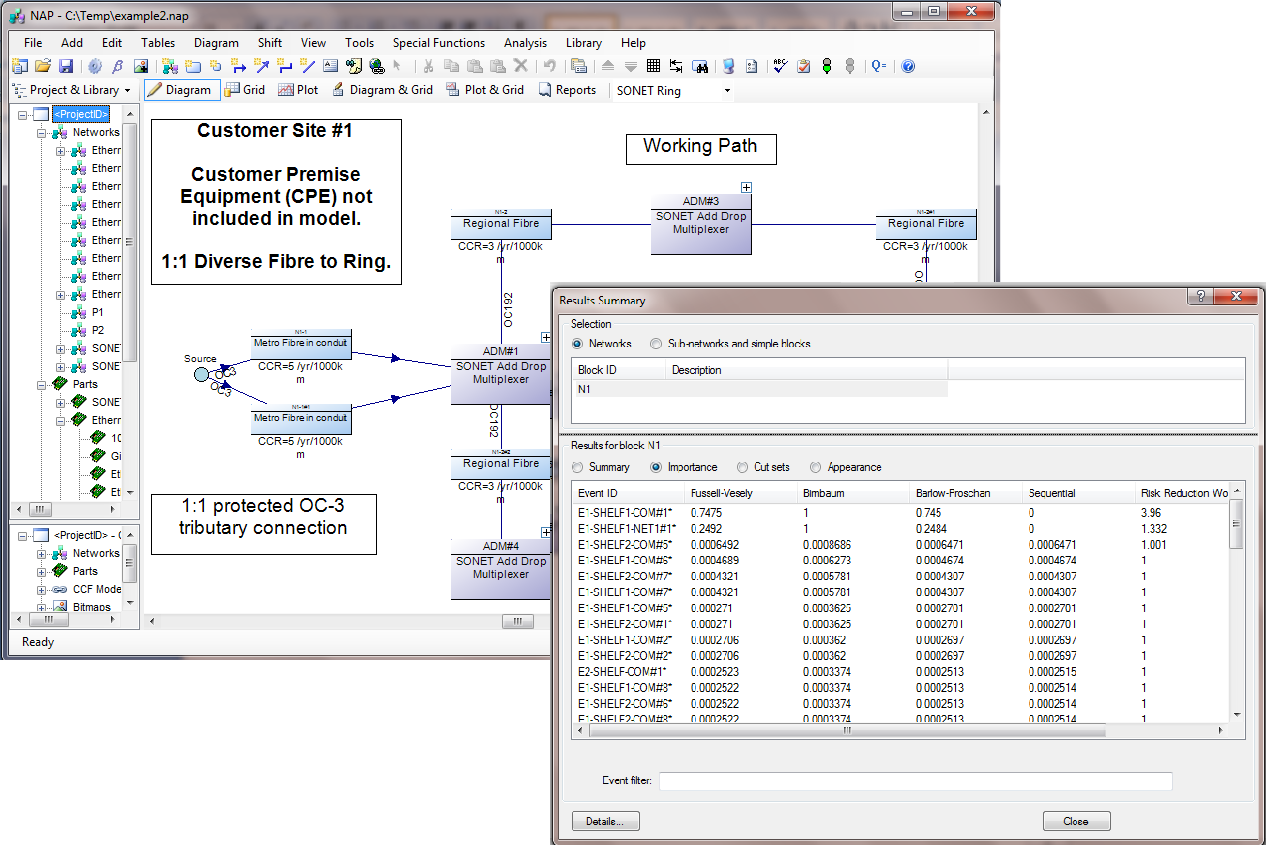

The Isograph reliability software products share a common facility to produce reports containing text, graphs or diagrams. Your input data and output results from reliability applications are stored in a database. This information can be examined, filtered, sorted and displayed by the Report Designer. The Report Designer allows you to use reports supplied by Isograph to print or print preview the data. A set of report format appropriate to the product is supplied with each product.

You can also design your own reports, either from an empty report page or by copying one of the supplied reports and using that as the starting point.

Reports may published or exported to PDF and Word formats.

As always please feel free to contact me if you have any questions: jhynek@isograph.com .