How does RCMCost Help?

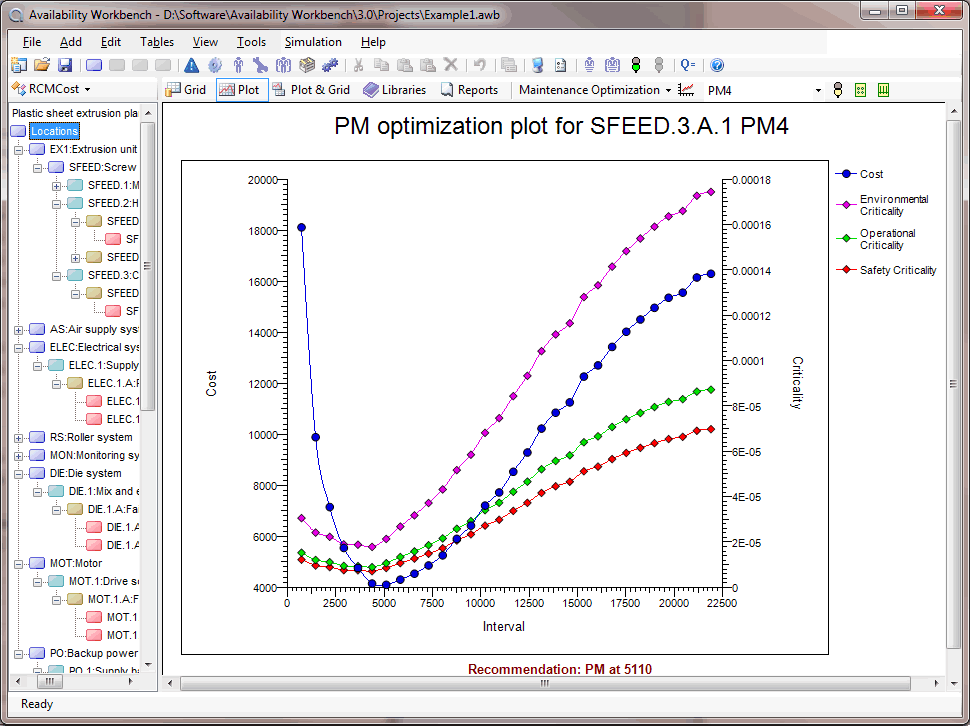

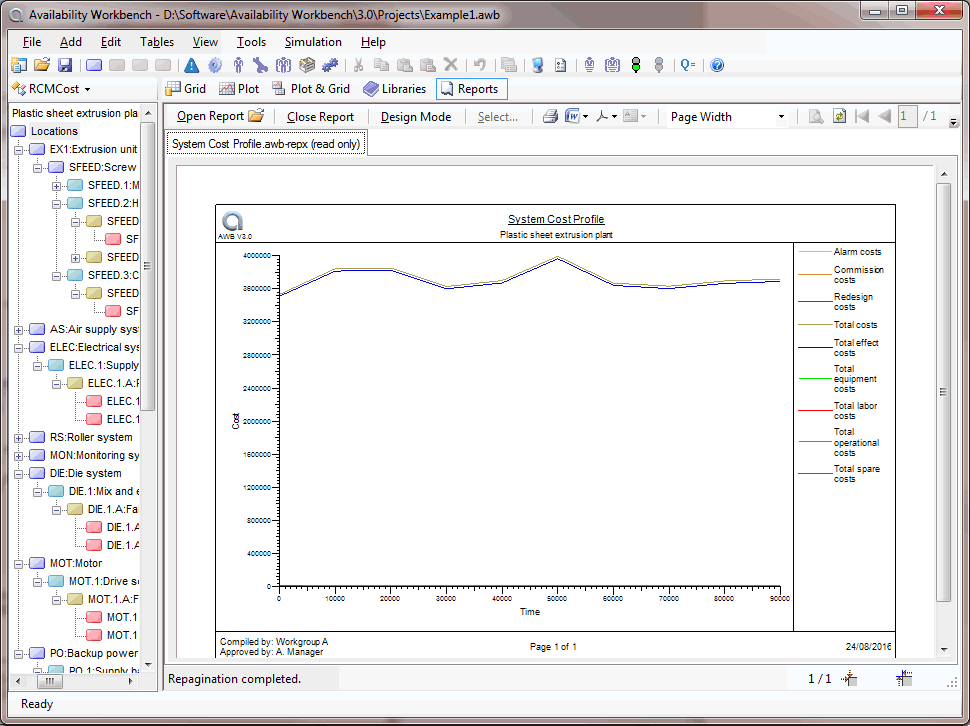

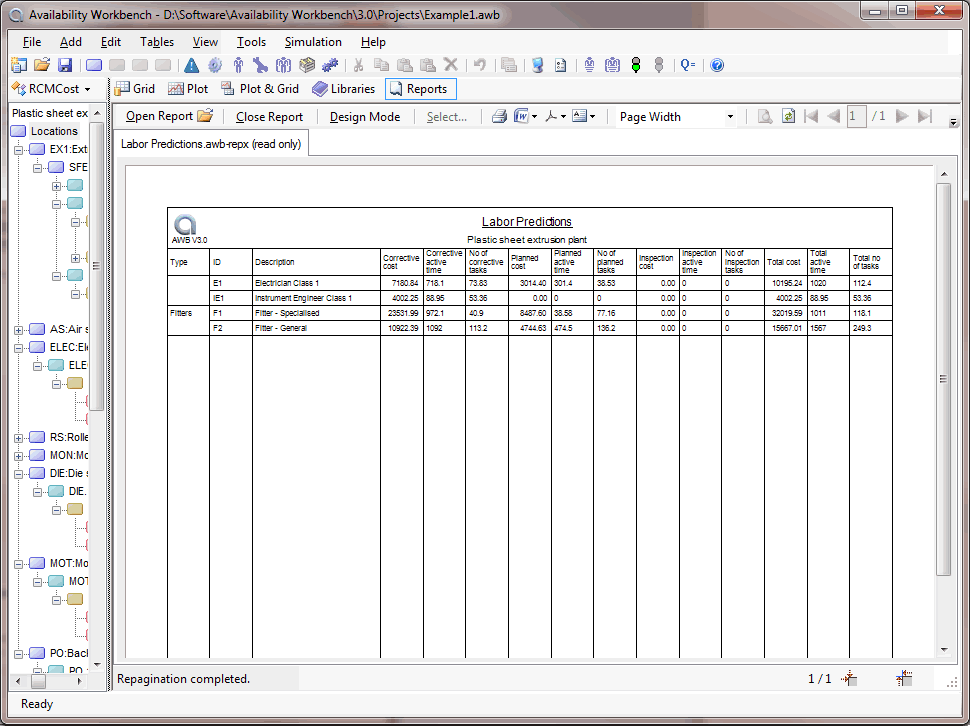

RCMCost in Availability Workbench provides facilities for storing RCM data and analyzing maintenance alternatives. It provides simulation algorithms to predict lifetime maintenance costs, spares costs and usage, maintenance crew manning requirements, safety and environmental risks and operational performance. In addition, RCMCost identifies critical failure modes and compares the cost, safety and operational benefits of different maintenance intervals.

The program is designed to combine well-established reliability prediction techniques with engineering experience. The program does not decide on which maintenance policy or combination of policies to adopt. Instead, it advises the individual user or workgroup based on the operational data provided. The program may be used to filter the most critical item (component) failures before detailed maintenance decisions are made.

Constructing a Hierarchy Diagram

RCMCost provides interactive graphical facilities for constructing a hierarchical diagram representing the logical connection between the sub-systems and items constituting the overall plant or system. This diagram may be extended to represent critical functions, their functional failures and their causes (engineering failure modes).

System effects are identified which contribute to outage and operational costs as well as safety and environmental risks. The relative severity of different effects is identified by the user. This structured method for identifying failure modes and linking them with their effects on the system is known asFailure Mode Effects and Criticality Analysis (FMECA) and is a powerful analysis process in its own right.

The RCMCost module allows flexible user-defined reports to be produced highlighting the most important contributors to operational costs and safety and environmental risks.

Other Features of RCMCost

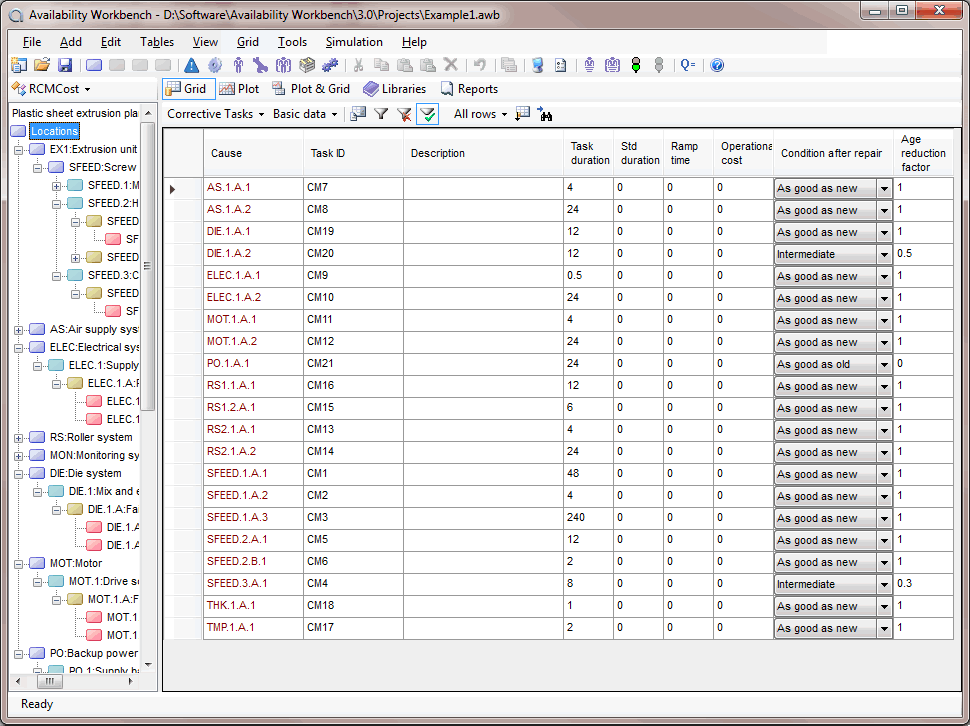

RCMCost provides a database facility for storing failure data, maintenance parameters, spares information and maintenance crew details. This data is used to provide advisory information based on simulation models incorporated in the program. For example, different maintenance intervals may be compared for their effect on maintenance and operational costs. The user may then record the decision on which maintenance policy (if any) to adopt. This decision may include combinations of:

- Scheduled Preventive Maintenance Tasks (Lubrication or Replacement)

- Condition Monitoring Alarms

- On-Condition Inspections

- Inspections for Hidden Failures

- Re-Design

RCMCost in Availability Workbench will automatically advise the user on the overall cost, safety and environmental benefits of adopting a particular maintenance policy based on the data provided by the user. The program’s flexible report facility allows RCM worksheets to be produced identifying the user’s decisions.

Once the maintenance policy has been decided for all the critical system components RCMCost will provide predicted spares requirements, maintenance crew manning levels, system costs and operational performance data.

As new data is gathered during the plant lifetime or system design changes are made RCM related data may be easily modified and maintenance procedures may be adjusted to reflect the living status of the plant.